Service hotline

+86-0417-7700208

Contact Mr. Zheng

Mobile: +86-13941703445

+86-13704073324

Tel: +86-0417-7700208

Fax: 0417-7701398

Postal Code: 115200

E-mail: gkjx7700208@163.com

Website : www.bggkjx.cn/en

Website: www.bggkjx.cn

Address: No. 4, Beishanzui Village, Dongcheng Street, Gaizhou City, Liaoning Province

STL-B wet desulfurization dust collector

First, use and characteristics

STL wet desulfurization dust collector is used for smoke elimination and flue gas desulfurization of industrial boilers.

The STL wet desulfurization dust collector has high efficiency and can reach more than 90%. When the amount of treated flue gas changes greatly, the efficiency of the precipitator remains almost unchanged. For dust of the same nature, the initial dust concentration has little effect on efficiency.

The dust collector has a compact structure and a small footprint, which is convenient for construction and installation. The water flow automatic control device and the mechanical automatic ash discharging device are adopted, and the workload of the furnace personnel is not increased, and the sanitary environment of the operation room can be well maintained.

Second, the working principle

The dusty flue gas enters the air inlet at a speed of 18-20 m/s and enters the sedimentation tank through the impact chamber. After the larger dust particles hit the water surface, they fall into the sedimentation tank. The flue gas is diffused and diffused through the S-shaped nozzle channel, and contacts the agglomeration, so that the soot exhaust gas and the water are in full contact with the mixture and settled. Most of the fine dust particles are mixed into the water, and are discharged by the automatic ash machine after the sedimentation. The flue gas is dehydrated through the clean room and then enters the induced draft fan. It is discharged from the chimney, and a certain amount of soda ash is dissolved in the ash hopper (added per 100 kg of water). 1 kg of sodium hydroxide) keeps the pH value of 11-13 antiseptic, which can make the desulfurization efficiency more than 80%. Dust is discharged every hour during operation.

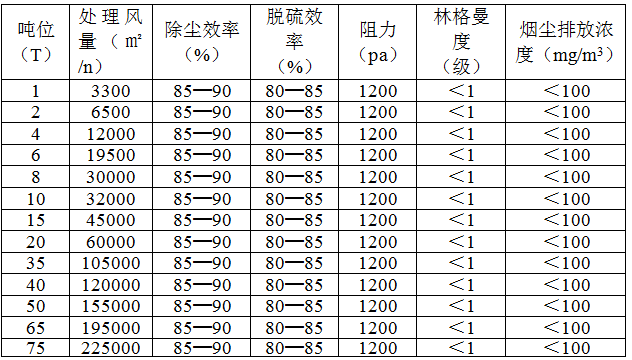

Third, the main technical indicators of technology

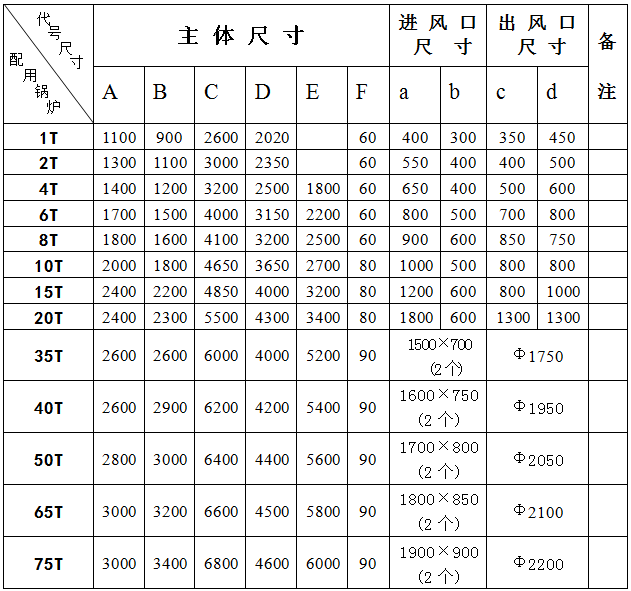

Fourth, the main technical specifications